Polycarbonate A High-Performance Engineering Plastic for Diverse Applications

|

| Polycarbonate |

Polycarbonate is a clear, tough and impact-resistant thermoplastic polymer containing carbonate groups in its chemical structure. It is often called "polycarb" for short or trade-named Lexan or Makrolon by major manufacturers. In this article, we will explore the properties, manufacturing process and various applications of polycarbonate and its widespread usage in modern engineering.

Physical and Chemical Properties

Some key physical and chemical properties of polycarbonate that make it popular for engineering applications include:

- Clear and transparent - Polycarbonate offers up to 87% light transmission which makes it a popular material for glazing and lighting products.

- Toughness - Polycarbonate has high impact strength even at low temperatures and retains its properties between -40°C to 120°C.

- Chemical Resistance - It has good resistance to acids, alkalis and hydrocarbons making it suitable for various chemical environments.

- Self-extinguishing - Polycarbonate has a high rating for the Underwriters Laboratories (UL) 94 flammability standard due to its self-extinguishing properties.

- Recyclable - Post-consumer scrap polycarbonate can be recycled and reused which makes it more environmentally sustainable.

Manufacturing and Processing

The most common method to produce polycarbonate sheets and films is by either calendaring or extrusion. In calendaring, the molten polycarbonate resin is extruded through a die and quenched before passing it through heated calendar rolls to obtain the desired thickness. Extrusion is used to make profiles, tubes, cast films and sheets where the melt is forced through a die and quenched directly without further processing. Some additional processing techniques used are:

- Injection molding - Used to manufacture complex parts with tight tolerances.

- Thermoforming - Heating polycarbonate sheets or films and forming them to make conformal parts using matched-metal dies.

These processing methods along with the self-reinforcing properties of polycarbonate allow it to be easily fabricated into intricate engineering components using basic workshop tools.

Engineering Applications

Due to the unique set of mechanical and thermal properties, Polycarbonate finds wide use in the following engineering domains:

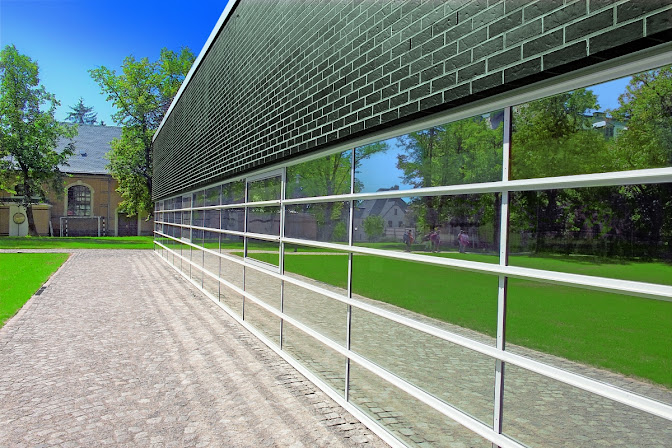

Construction

- Glazing and fenestration - Polycarbonate sheeting is used to make greenhouse glazing, skylights, fencing etc.

- Lighting devices - Components in street lighting, overhead lighting etc.

- Infrastructure - Membrane structures, railings, signage panels.

Automotive

- Headlight lenses - High light transmission and durability make it suitable.

- Instrument panels - Gauges, switch panels benefit from light weight and clarity.

- Exterior components - Grilles, badges, mirror housing use polycarbonate.

Electrical and Electronics

- Connectors and housings - Resists heat and protects internal components.

- Wire insulation - Self-extinguishing properties ensure safety.

- Circuit boards and semiconductor packages.

Optics and Photonics

- Lenses - Used in eyeglasses, microscopes, binoculars due to light weight and high clarity.

- Prisms and mirrors - Excellent surface quality for directing or splitting light beams.

Safety and Personal Protective Equipment

- Safety goggles, visors and shields - Durable, clearer vision and face protection.

- Reflective vests, helmets - Lightweight impact resistant enclosures.

Get more insights on Polycarbonate

Also read related article on Microsegmentation Market

%20Treatment%20(1).jpg)

Comments

Post a Comment