Beyond the Hype: The Practical Applications and Challenges of 3D Printing in Everyday Life

|

| 3D Printing |

In recent years, 3D printing has gained considerable

attention as a groundbreaking technology that promises to revolutionize

industries and reshape how products are made. Once considered futuristic, 3D

printing is now a practical tool used in diverse sectors, from healthcare to

construction, fashion, and even food production. However, beyond the initial

excitement lies a deeper conversation about the real-world applications and

challenges of this technology.

This blog will explore how 3D printing is impacting

everyday life, its practical benefits, and the challenges that need to be

addressed to unlock its full potential.

What is 3D Printing?

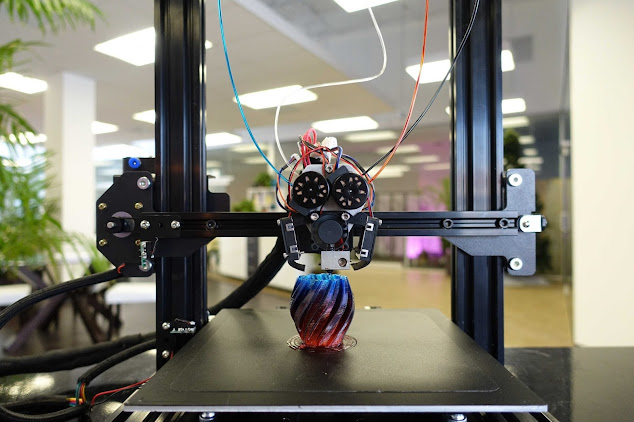

At its core, 3D printing, also known as additive

manufacturing, is a process where a digital design is transformed into a

physical object by layering materials like plastic, metal, or resin. Unlike

traditional manufacturing methods that cut or mold materials, 3D printing

builds objects layer by layer, offering greater flexibility and precision.

The process typically starts with creating a digital

model of the object using computer-aided design (CAD) software. Once the design

is complete, the printer uses the chosen material to construct the object based

on the blueprint. The ability to customize designs and produce complex

geometries that are difficult or impossible to achieve through traditional

methods makes 3D printing a powerful tool in many industries.

Practical Applications of 3D Printing

While 3D printing is often associated with rapid

prototyping and industrial uses, it has practical applications in everyday life

that are transforming how products are designed, created, and consumed.

1. Healthcare Innovations

One of the most exciting applications of 3D Printing

is in healthcare, where the technology is used to create customized medical

devices, implants, and even prosthetics. For instance, 3D-printed prosthetics

are more affordable and accessible than traditional prosthetics, particularly

for children who outgrow their devices quickly. Medical professionals are also

using 3D printing to produce patient-specific implants and surgical models,

which can improve surgical precision and reduce recovery times.

Additionally, researchers are experimenting with

bioprinting, a cutting-edge branch of 3D printing that uses living cells to

create tissue structures. While still in the experimental phase, this

technology could one day enable the printing of organs, revolutionizing organ

transplants.

2. Customized Consumer Goods

3D printing has enabled a new wave of customization

in consumer goods, ranging from jewelry and fashion accessories to home decor

and electronics. This customization allows consumers to design and personalize

products tailored to their unique preferences, from custom-fit eyewear to

3D-printed shoes that mold to the wearer’s foot shape.

For small-scale manufacturers and hobbyists, desktop

3D printers provide an affordable way to create unique products without the

need for mass production or expensive tooling. Online platforms and communities

have also emerged, where people can share and download design files, further

democratizing access to personalized manufacturing.

3. Education and Learning

3D printing is being integrated into classrooms and

educational institutions, offering students hands-on experience in STEM

(Science, Technology, Engineering, and Math) subjects. The ability to design

and print tangible models helps students understand abstract concepts, such as

geometry, physics, and engineering. For instance, students can 3D-print models

of molecules, historical artifacts, or architectural structures, enhancing

their learning experience.

In addition to traditional education, 3D printing is

helping bridge gaps in vocational training, allowing students to practice

design, engineering, and fabrication skills that are directly applicable in

today’s job market.

4. Food Printing

While it may sound like something from a science

fiction movie, 3D food printing is becoming a reality. Chefs and food companies

are experimenting with this technology to create intricate designs and textures

that are difficult to achieve through traditional cooking methods. By layering

edible materials like chocolate, dough, and purees, 3D printers can create

customized meals, pastries, and snacks.

In the future, 3D food printing could help address

global food shortages by providing a sustainable way to produce food using

alternative ingredients like plant proteins and insects. Additionally, food

printing could be used to create personalized meals for individuals with

dietary restrictions, such as gluten-free or low-sodium options, without

sacrificing flavor or presentation.

5. Construction and Housing

3D printing is pushing the boundaries of

architecture and construction, allowing for the creation of complex structures

that are both cost-effective and environmentally friendly. Using large-scale 3D

printers, construction companies are building homes and other structures by

printing layers of concrete or other materials. This approach reduces waste,

speeds up construction time, and lowers labor costs.

In disaster-prone regions, 3D printing could offer a

solution to housing shortages by enabling the rapid construction of affordable,

durable shelters. The technology’s ability to produce homes in just a matter of

days could be a game-changer for addressing housing crises around the world.

Challenges Facing 3D Printing

Despite its vast potential, 3D printing still faces

several challenges that need to be addressed before it can reach mainstream

adoption across various sectors. Some of these challenges include:

1. Material Limitations

Currently, 3D printing is limited by the range of

materials that can be used in the process. While plastics, metals, and resins

are commonly used, not all materials can be 3D-printed, and those that can may

not always meet the durability, flexibility, or strength requirements for

certain applications. Additionally, the quality of 3D-printed products can

sometimes be inferior to those produced using traditional manufacturing

methods.

Research is ongoing to develop new materials that

can expand the capabilities of 3D printing, such as biodegradable materials,

stronger composites, and conductive materials for electronics.

2. Production Speed

While 3D printing offers flexibility and

customization, the process can be slow, particularly for larger objects or when

using certain types of materials. In traditional manufacturing, products can be

mass-produced rapidly using assembly lines, whereas 3D printing is typically a

one-off process that builds objects layer by layer. This slow production speed

can limit its application in mass production environments.

Efforts are being made to improve the speed of 3D

printing through new technologies like multi-head printers, faster curing

processes, and more efficient material deposition techniques.

3. Cost and Accessibility

While the cost of desktop 3D printers has dropped

significantly in recent years, industrial-grade 3D printers remain expensive.

The materials used in 3D printing can also be costly, particularly for

high-quality or specialized applications. As a result, small businesses and

hobbyists may find the upfront investment prohibitive, limiting their ability

to fully explore the technology’s potential.

Making 3D printing more accessible will require

continued innovation in both printer technology and materials to reduce costs

and expand the range of affordable applications.

4. Intellectual Property Concerns

As 3D printing becomes more widespread, issues

related to intellectual property (IP) are emerging. Because 3D printing allows

users to replicate objects from digital files, there is a risk of unauthorized

copying and distribution of patented or copyrighted designs. This has raised

concerns among designers, manufacturers, and industries that rely on IP

protection, such as fashion, electronics, and entertainment.

To address these concerns, new regulations and

technologies, such as digital watermarking, are being developed to safeguard

intellectual property in the world of 3D printing.

3D printing holds immense promise, offering creative

solutions to challenges in healthcare, manufacturing, construction, and beyond.

While the technology has already made significant strides in various

industries, its true potential has yet to be fully realized due to material

limitations, speed issues, and cost concerns.

However, as research and development continue to

push the boundaries of what is possible, 3D printing is poised to become a

critical tool for innovation in everyday life. Whether it’s producing

customized medical devices, creating sustainable housing solutions, or

revolutionizing food production, 3D printing is no longer just hype—it's

shaping the future of how we design, create, and live.

For

Enhanced Understanding, Dive into the Report in the Language that Connects with

You

About

Author:

Money Singh is a seasoned content writer with over four years of

experience in the market research sector. Her expertise spans various

industries, including food and beverages, biotechnology, chemical and

materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

%20Treatment%20(1).jpg)

Comments

Post a Comment